Non-Ferrous Casting and Permold Capabilities

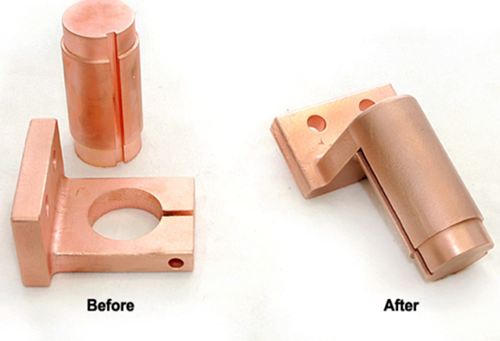

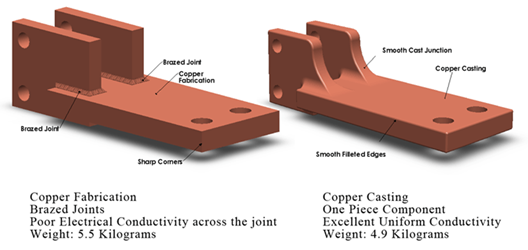

S&V has formed strategic supply chain partnerships for manufacturing and assembly capabilities to fit this industry. These partnerships have been forged over the past 25 years and are backed by ISO listed quality based low cost sources. For the OEM that needs Non-Ferrous castings, we offer R&D and build from print. No project too large and we can also take complex multi welded part and build a single casting solution reducing cost and improving performance. In addition employing S&V’s supply chain for total cost of ownership and managed local warehoused inventory, We can reduce your time and material costs. For more information please download our presentation on these capabilities.

- Con-Cast Process — A resistance melting process where melting is carried out in a graphite crucible. Melting in graphite crucible provides a reducing environment for cleaner melts. The process is completely PLC controlled, where the cast parameters are stored and recalled enabling reproducible heats (properties)

- Permold Process — Permanent mold process consists of pouring liquid metal into metal molds dressed with a suitable coating under the influence of gravity, therefore, this process is also termed as gravity die casting.

- Unlike the sand castings, the molds in permanent mold process are re-usable and therefore, cost effective for bulk production runs.

Every partner in our supply chain is:

- ISO certified along with other industry certs

- Technically sound in the product fields and has been in business for over 25yrs.

- Equipped with an engineering staff for design support and review

- Able to supply First Articles for review

- Copper Alloy

- R2 & R0

- CDA Standard C80100

- High Copper Alloys

- R40 & R75

- CDA Standard C81400 & C84500

- Aluminum Bronze

- RA001

- CDA Standard C95300 & C95400

- RA002

- CDA Standard C95500 & C95800

- High Tensile Brass

- RB001, RB002, RB003 7 RB005

- CDA Standard C86100, C86200, C86300, C86400 & C86500

- Fully integrated plating process for Cu, Al and other castings.